class ii division 2 group g

NEC Class II Divisions 1 2 Groups E F G. In that case the area would be categorized as a Class II Division 2 Group G.

Division II because flammable vapor would only leak from the tanks if there was an accident.

. E2x non-sparking devices now for Class I. 02 2022 100 pm. Class II Div II receps in cabinet shops Ive been reading a lot on article 502-115 502-145 and speaking to the local authorities on the requirement for receptacles around wood working equipment.

NEC Class II Division 2 Groups F G. They are calling it Class II Div II group G My question is do I have to use explosion proof receptacle or do they make something more. However Class 1 and 2 motors are grouped by your specific hazardous substance.

Class II locations are those that are hazardous because of the presence of combustible dust. NEC Class II Divisions 1 2 Groups F G. Group F is for carbonaceous dust like charcoal coal and carbon black.

For outdoor application in Class II Div2 Group G you can very well use combination of NEMA 4 very approximate equivalent to IP 66 NEMA 9 For hazardous locations enclosure. Football commits for D2 D3 and more. Group II is for explosive gases Zone 0 1 and 2 and Group III.

ClassDivision Hazardous Location 6 Note. NEC Class II Divisions 1 2 Groups E F G. We offer a comprehensive solution service which includes extrusion design manufacture software programming and project management support.

Jun 17 2009. National Signing Day 2022. Propane tank storage room.

I recognize that temperature limitation will always apply however dust accumulations are not permitted in a Division 2 environment. Class II Division 2 is where. Group is divided in three groups where Group I is reserved for mining locations.

Class II Group G. Locations with combustible dusts. Class II Group G.

Article 5005C22 3 where combustible wood dust is present however under normal conditions the environment is maintained so the combustible dust does not accumulate or interfere with operations. Choose from our selection of Class II Division 2Group G switches in a wide range of styles and sizes. Choose from our selection of CSA certified Class 2 group G switches in a wide range of styles and sizes.

Division I because dust is present during normal operation. Combustible dusts not in group E or F. Locations with ignitable fibers and flyings.

D1xB2 range - Class I II Division 1 Zone 1 21 Xenon strobes and LED beacons. Where ignitable dust or vapors may be present. Note that the dust must be present in.

Per the National Electrical Code NEC there are 3 classifications for areas that are defined as hazardous. Class II locations are divided into three groups EFG. We have experience in large turnkey solutions for Class 1 Division 2 and ATEX Zone 2 environment projects be sure to give us a call 44 0 1785 879 050 UK or 1 864 421 6991 US to discuss yours.

Atmospheres containing combustible dusts not included in Group E or Group F including flour grain wood plastic and chemicals. These fine particles can float and collect on equipment in the surrounding areas. Class II location groups are determined by.

Class i div 1 abcd class iiiii div 1 efg atexiecex g zone 1 iic d zone 22 iiic series 5c valve status monitor nec class i div 1 abcd class ii div 1 efg atexiecex g zone 1 iibh2 d zone 21 iiic series 63 solenoid nec class i div 1 abcd class ii div 1 efg intrinsically safe products12 energy limited ex ia series 6a positioner. Any grounding provisions must be in the main conduit box. Motor accessories must be non-sparking or approved for Explosion Proof XP duty.

Atmospheres containing combustible carbonaceous dusts such as coal carbon black charcoal and coke dusts. 2 provide this equipment with enclosures that are dusttight or identified for the location 502115 502120. Class II Division 1 is in an area where dust material is handled manufactured or used.

The IP rating and Explosionproof rating are different. They are Class I gases vapors Class II flammable dusts Class III fibers the focus of todays Blog is on Class II locations. Motors suitable for Class II Groups F G Division 2 are available in TEFC TEFC-XT TEBC TEAAC and TEWAC only.

All IP67 rating equipments can not be used in classified area. Class II Division 2- Designed for the safe collection of combustible dust where the dust is not suspended in an ignitable concentration. Group G because grain dust is in the atmosphere.

Combustible fibres and flyings. 1 locations provide electrical controls eg switches breakers control transformers and resistors with enclosures identified for use in the location 502115 502120. Class II Division 2 Groups F.

Group D because propane is in the atmosphere. If the dust removal system sufficiently. NEC Zone 1.

Every flammable gas or vapor has specific lower and upper flammability limits. Class I because of flammable vapor. NEC Class II Division 2 Groups F G.

Group define the type of hazardous material and partly the location of the surrounding atmosphere. Class II because of combustible dust. NEC Class III Divisions 1 2.

The most common groups and materials are listed below. 02 2022 401 pm. As required by Underwriters Laboratories and Canadian Standards Association explosion-proof motors with Class II Group F G approvals must have over temperature protection.

If the substance or concentration in the oxidizer is either below a specific value lower flammability limit or above a spe cific value upper flammability limit. In stock and ready to ship. NEC Zone 1.

In Class II Div. Class II Group F G locations are atmospheres containing dust such as F Carbon Black coal or Coke Dust G Flour Starch or Grain Dusts. The ignition temperature of the dust the electrical conductivity of the dust and the thermal blanketing effect the dust can have on heat-producing equipment such as.

Indoor or outdoor use in locations classified as Class I Division 2 Groups A B C or D hazardous locations as defined in. I cannot find any reliable source to come out and specifically say that NEMA 12 or NEMA 4 enclosures are suitable for use in Class II Division 2 Group G environments. NEC Class III Divisions 1 2.

And Group G is for non-conductive dust like flour grain and plastic. NEC Class II Divisions 1 2 Groups F G. Material Groups Dust Class II Group F.

In stock and ready to ship. HD090818-20 Rev0 NEMA 9 Indoor use in locations classified as Class II Division 1 Groups E F and G hazardous locations as defined in the National Electric Code NFPA 70 commonly referred to as dust-ignition proof. The Class 3 motor is the least common and isnt divided any further into groups.

Class III Division 12 - Certified for use in classified environements for the safe collection of combustible dusts. Kyle Vellis 10 of.

Practical Guidelines For Determining Electrical Area Classification

Practical Guidelines For Determining Electrical Area Classification

Ul And C Ul Hazardous Areas Certification For North America Ul

Ul And C Ul Hazardous Areas Certification For North America Ul

Practical Guidelines For Determining Electrical Area Classification

Ul And C Ul Hazardous Areas Certification For North America Ul

Ul And C Ul Hazardous Areas Certification For North America Ul

The Best Headlamps For Hazardous Environments In 2021 Underwater Kinetics

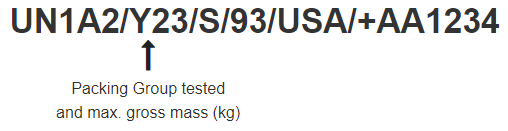

Packaging Your Dangerous Goods Federal Aviation Administration

Practical Guidelines For Determining Electrical Area Classification

Ul And C Ul Hazardous Areas Certification For North America Ul

Ul And C Ul Hazardous Areas Certification For North America Ul

Practical Guidelines For Determining Electrical Area Classification

Hazardous Location Classification

Ul And C Ul Hazardous Areas Certification For North America Ul

Practical Guidelines For Determining Electrical Area Classification

Self Regulating Heating Cables Approved For Use In Hazardous Locations Briskheat